Home » Our activities » Treatment and recovery of waste

Leroux & Lotz

Treatment and recovery of waste

Revamping of existing facilities linked to the evolution of the fuel or the increase in capacity and design and build of a new incineration line

2013 UVE Villejust – upgrading existing grate fired boilers including increase in the MSW treatment capacity 15%, improving the availability to over 95% as well as the overall energy performance above 85%

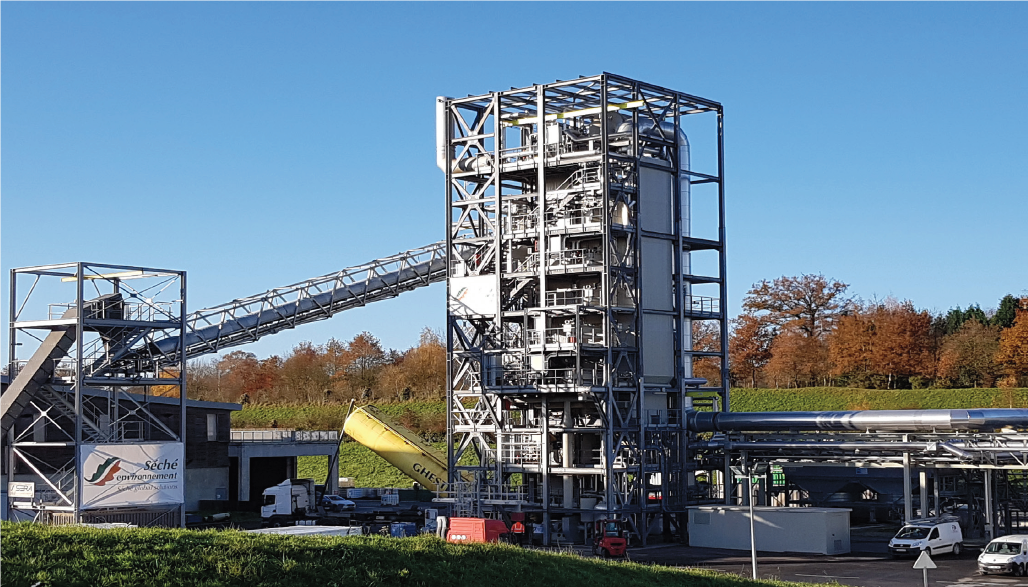

System for combustion or gasification of industrial waste, SRF or RDF

2017 SECHE Change (F): First SRF fired boiler in France - Circulating fluidized bed of 15MW with production of saturated steam 12 bar supplying district heating and agro-industry - 12,500 ton of CO2 emissions avoided per year.

2016 ESKA Hoogezand (NL): Recovery of waste paper reject using circulating fluidized bed in gasification mode, producing 12 MW of 16 bar saturated steam supplying the paper making process – annually 25,000 to of waste recovered in replacing approx. 30% of the plants natural gas consumption resulting in a 67% drop in CO2 emissions.

Waste treatment by hydrothermal oxidation

2020 Atlantic shipyards: LLT HydroThermal Oxidation (OHT) unit is able to treat liquid waste (such as food waste and bio-Sludge) produced on board in a more environmentally friendly manner when compared to the usually discharge methods. Following the success of the tests carried out with the demonstrator installed on board the award-winning CelebrityEDGE cruise ship (5,000 people capacity), an order for 1 unit for it sister-ships under manufacturing, was finalized in 2020.

2020 - Neovaly, Rillieux-la-Pape (FR): Improvement of the two lines - Optimisation of the availability from 90% to 96%, improvement of the energy performance of the installations, replacement of the gas for the reheating of the flue gases by an integration of an RCU exchanger.

2019 - Valaxion, Besançon (FR): Renovation of the production line - Optimisation of production, increase in availability by 63%, increase in thermal production by 8%, increase in electricity production by 4% and reduction of environmental impact and decrease in NOx from 200 to 50 mg/Nm3. Sludge is now treated by incineration.